PPTC Resettable Fuses

|

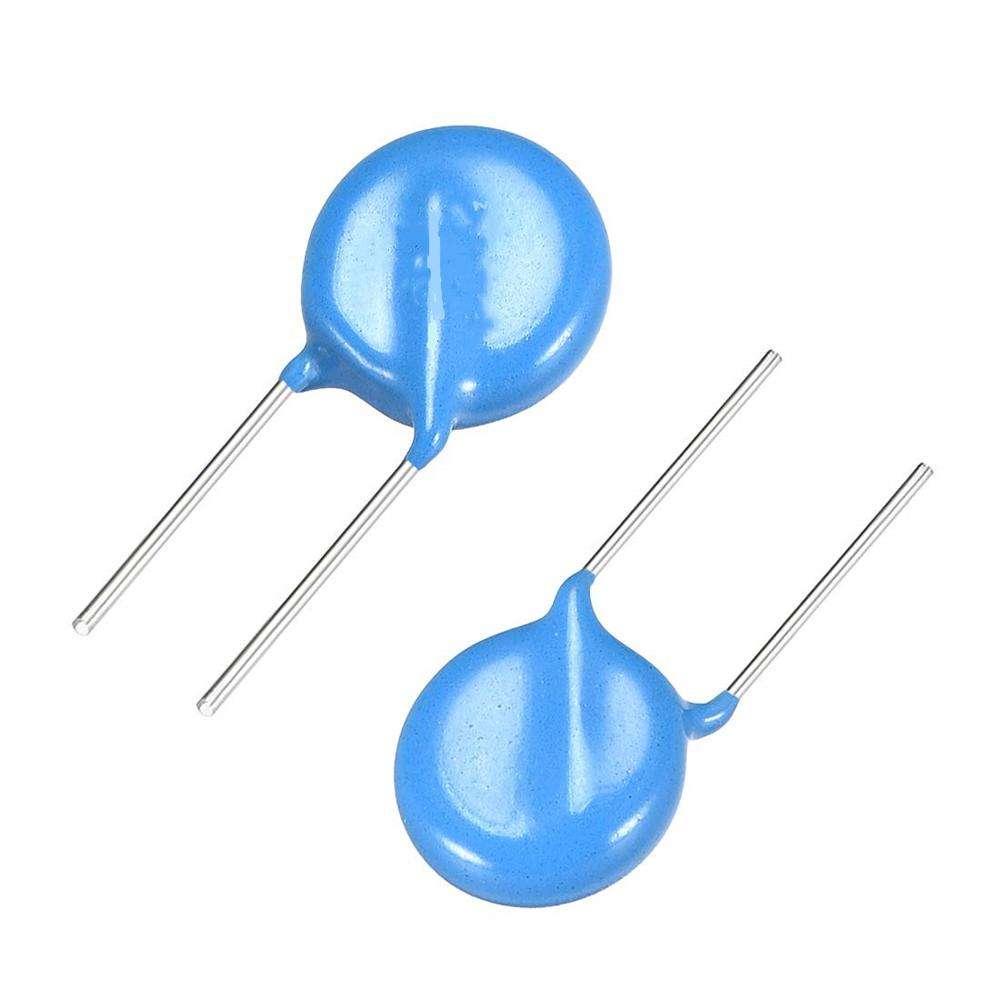

Information of PPTC The selection tips of PPTC/FUSE 1. Determine the following circuit operating parameters: Normal operating current – IHOLD Maximum circuit voltage – VMAX Maximum interrupt current – IMAX Ambient operating temperature 2. Select the suitable package SMD or DIP. 3. Compare the PTC data sheet ratings for VMAX and IMAX to ensure that the circuit parameters do not exceed these ratings. 4. Verify that the ambient operating temperature within close proximity to the device is within its normal operating range. Thermally derate IHOLD and IMAX as necessary. |

| Part Number |

Ih(A)

|

Vmax(Vdc)

|

Imax(A)

|

Trip current(A)

|

Trip time(s)

|

Rmax(Ω)

|

Rmin(Ω)

|

Pdtyp(W)

|

It(A)

|

Package

|

Inner Diagram | Data sheet |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HL60-005 | 0.05 | 60 | 40 | 0.25 | 8 | 20 | 7.3 | 0.26 | 0.15 | DIP |

|

|

| HL06-075 | 0.75 | 6 | 40 | 8 | 0.4 | 0.345 | 0.14 | 0.3 | 1.3 | DIP |

|

|

| HL06-090 | 0.9 | 6 | 40 | 8 | 1.2 | 0.27 | 0.1 | 0.6 | 1.8 | DIP |

|

|

| HL06-110 | 1.1 | 6 | 40 | 8 | 2.3 | 0.21 | 0.08 | 0.7 | 2.2 | DIP |

|

|

| HL06-120 | 1.2 | 6 | 40 | 8 | 3.5 | 0.21 | 0.08 | 0.6 | 2 | DIP |

|

|

| HL06-135 | 1.35 | 6 | 40 | 8 | 4.5 | 0.18 | 0.06 | 0.81 | 2.7 | DIP |

|

|

| HL06-160 | 1.6 | 6 | 40 | 8 | 9 | 0.165 | 0.05 | 0.9 | 3.2 | DIP |

|

|

| HL06-185 | 1.85 | 6 | 40 | 8 | 10 | 0.135 | 0.05 | 1 | 3.7 | DIP |

|

|

| HL06-250 | 2.5 | 6 | 40 | 8 | 40 | 0.09 | 0.03 | 1.21 | 5 | DIP |

|

|

| HL60-010 | 0.1 | 60 | 40 | 0.5 | 5 | 7.5 | 2.5 | 0.38 | 0.3 | DIP |

|

|

| HL60-017 | 0.17 | 60 | 40 | 0.85 | 5 | 5.21 | 2 | 0.48 | 0.34 | DIP |

|

|

| HL60-020 | 0.2 | 60 | 40 | 1 | 5 | 2.84 | 1.5 | 0.41 | 0.4 | DIP |

|

|

| HL60-025 | 0.25 | 60 | 40 | 1.25 | 5 | 1.95 | 1.0 | 0.45 | 0.5 | DIP |

|

|

| HL60-030 | 0.3 | 60 | 40 | 1.5 | 5 | 1.38 | 0.76 | 0.49 | 0.6 | DIP |

|

|

| HL60-040 | 0.4 | 60 | 40 | 2 | 5 | 0.88 | 0.45 | 0.56 | 0.8 | DIP |

|

|

| HL60-050 | 0.5 | 60 | 40 | 2.5 | 5 | 0.79 | 0.4 | 0.77 | 1.0 | DIP |

|

|

| HL60-065 | 0.65 | 60 | 40 | 3.25 | 5 | 0.50 | 0.31 | 0.88 | 1.3 | DIP |

|

|

| HL60-075 | 0.75 | 60 | 40 | 3.75 | 5 | 0.42 | 0.25 | 0.92 | 1.5 | DIP |

|

|

| HL60-090 | 0.9 | 60 | 40 | 4.5 | 5 | 0.33 | 0.2 | 0.99 | 1.8 | DIP |

|

|

| HL60-110 | 1.1 | 60 | 40 | 5.5 | 8 | 0.27 | 0.15 | 1.5 | 2.2 | DIP |

|

|

| HL60-135 | 1.35 | 60 | 40 | 6.75 | 8 | 0.21 | 0.12 | 1.7 | 2.7 | DIP |

|

|

| HL60-160 | 1.6 | 60 | 40 | 8 | 8 | 0.16 | 0.09 | 1.9 | 3.2 | DIP |

|

|

| HL60-185 | 1.85 | 60 | 40 | 9.25 | 8 | 0.14 | 0.08 | 2.1 | 3.7 | DIP |

|

|

| HL60-200 | 2 | 60 | 40 | 10 | 8 | 0.14 | 0.07 | 2.3 | 4 | DIP |

|

|

| HL60-250 | 2.5 | 60 | 40 | 12.5 | 8 | 0.1 | 0.05 | 2.5 | 5 | DIP |

|

|

| HL60-300 | 3 | 60 | 40 | 15 | 8 | 0.08 | 0.04 | 2.8 | 6 | DIP |

|

|

| HL60-375 | 3.75 | 60 | 40 | 18.75 | 24 | 0.06 | 0.03 | 3.2 | 7.5 | DIP |

|

|

| HL60-500 | 5 | 60 | 40 | 25 | 24 | 0.06 | 0.02 | 3.5 | 10 | DIP |

|

|

| HL600-110 | 0.11 | 600 | 3 | 1 | 8 | 16 | 6 | 1 | 0.22 | DIP |

|

|

| HL600-150 | 0.15 | 600 | 3 | 1 | 9 | 14 | 5 | 1 | 0.3 | DIP |

|